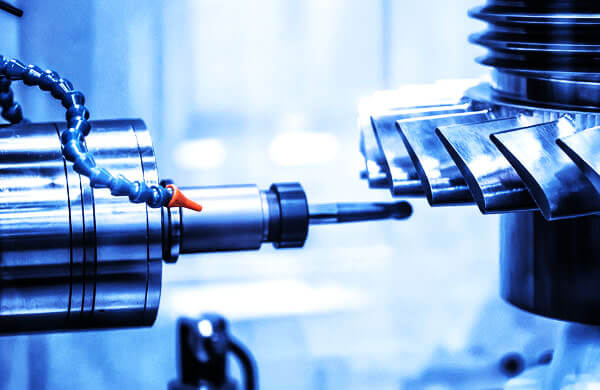

Zetwerk provides high-quality die-cast components produced using a range of materials including aluminum, zinc, copper, brass, and bronze alloys. Once a component has been die-cast, it can be further refined with CNC machining. Surface finishes are commonly applied through processes like shot-blasting, texturing, plating, and painting.

Zetwerk offers a comprehensive range of investment casting services tailored to your unique requirements. Our services include prototype development, tooling, casting, machining, and finishing, and we ensure the delivery of the best quality investment cast components using ferrous and non-ferrous alloys.

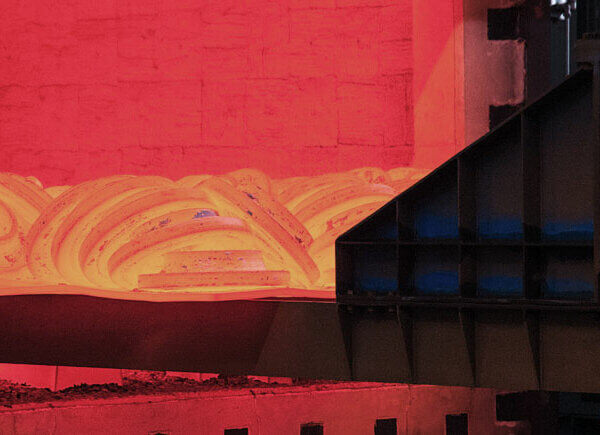

Zetwerk manufactures top-quality forged components efficiently and effectively. Because of our team’s proficiency in tool design and the usage of top-tier industry software, Zetwerk can guarantee that the tools used in production will consistently produce flawless components. Zetwerk takes excellent care to ensure that forged parts’ chemical composition, dimensional stability, mechanical qualities, and structural integrity are based on customer requirements.

Contract manufacturing is when a manufacturer contracts with another business to produce certain parts or goods over a predetermined timeframe. A contract manufacturer, which is regarded as a type of outsourcing, may enter into a business relationship with a company to produce parts, components, or entire products for the firm in accordance with their specifications.

Zetwerk offers coiled or blanked sheet metal custom precision Components. We can make sheet metal components in large or small quantities by bending, cutting, and welding the metal. The process of sheet metal involves pressing and stamping metal blanks into the final shape that is required utilizing tools and dies. Many different industries, including automotive, aerospace, consumer electronics, and electronic manufacturing, frequently use sheet metal services.

Zetwerk is a manufacturer specializing in Metal Injection Molding (MIM), a process that combines plastic injection molding with the strength of metal. Using a mixture of metal powders and binders, creating feedstock which is then injected into molds. After the injection, the molded parts are subjected to heat treatment to remove the binders and sintered for achieving the desired metal density. This process allows Zetwerk to produce intricate and precise metal components for various industries, such as automotive, medical, and electronics.